New technologies, new solutions

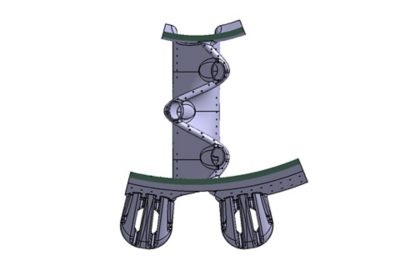

Dreaming of big and heavy additive parts for the next generation of gas turbines?

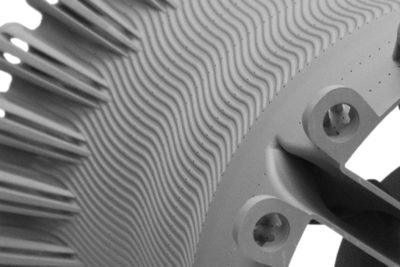

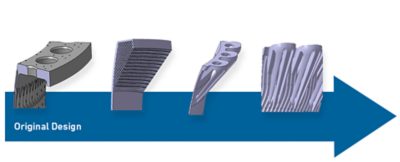

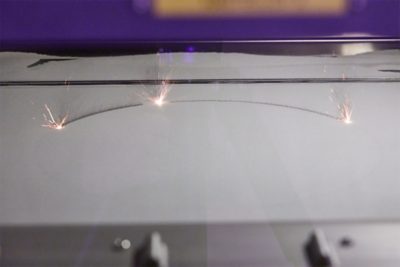

The additive manufacturing process maximizes the design flexibility and allows the integration of additional functions - at no additional costs for extra geometry changes as no prior models or tools are needed. Geometries are no longer limited to the possibilities of traditional technologies.

In addition, with printing space as big as 500 x 500 x 500 mm, we offer serial production of large additive manufactured components with extremely complex shapes integrating more details and functions.