Iron casting

Innovative iron components for your application

The global demand for innovative iron components is rising. GF Leipzg supports their customers in the development and production of high-complex iron solutions. Casting technology is the best choice for a high level of functional integration in complex components. We develop and produce optimized solutions for various applications by offering the whole value chain.

Value add in iron casting

Value add in sand 3D-printing for iron casting

More information about Sand 3D-printing for iron casting solutions

With the serial production of 3D-printed sand cores for sandcasting processes, GF Casting Solutions is your reliable partner providing know-how and state-of-the-art technology with a twin job box providing a build volume of 1,800 x 1,000 x 700 mm each.

Moreover, GF Casting Solutions agreed on a long-term development partnership with ExOne GmbH to quickly benefit from future development of the technology and to bilaterally improve the production processes. Our customers benefit from the time and cost reductions for prototypes and spare parts, higher process reliability—no assembly of cores—and virtually infinite freedom of design.

Cold-hardening phenol 3D printer

| Build Box | 1800 x 1000 x 700 mm |

| Material | Cerabeads (Ceramic Sand) Silica Sand |

| Layer | 0.26 mm |

Production cost reduction

By using prototypes to test your product beforehand, you can eliminate potential flaws already in the design phase which, in the end, will reduce the overall costs.

Shorten time-to-market

Using prototypes in the development phase will not only reduce costs, but the time-to-market, too. All the learnings from the prototype phase will save time and resources when you start with the serial production.

Close to serial conditions

Without the limitations of conventional core making technology, previous multiple-part components can be fused to one single part, increasing integrity and reducing weight and costs.

Consulting service

If you lack the experience with additive manufacturing for prototypes, our dedicated team of experts is happy to assist you either with creating your design or help you to further optimize it according to the 3D printing process. Please get in touch with us.

Materials

Together with our partners, we can offer a variety of alloys for the reliable and flexible production of prototypes under serial conditions. New geometries are not only beneficial for new products, but open up completely new areas of application. Get in touch with our experts to learn more!

Freedom of design

Additive technology allows us to create extremely complex geometries with no additional effort. Through design and engineering know-how and the use of latest technology, we create your product with exactly the design you need.

Our value chain

- Do you need support in component development?

- Do you need a fully functional prototype fast?

- Do you need large & complex parts with high quality?

From the idea to series production, we supply everything out of one hand - GF Casting Solutions Leipzig operates the foundry with Europe's largest molding box for machine-molded iron casting. We offer all processes under one roof - from prototyping & sand 3D-printing, to series production in iron casting, coating and machining of components.

No matter what challenges you face, GF Casting Solutions supports you throughout the supply chain and strive to become your development partner. We offer comprehensive know-how and competencies for several market segments like construction equipment, forest and agricultural machines, hydraulics or robotics. Learn more about our process chain for prototyping and series production.

We are your partner throughout the entire value chain

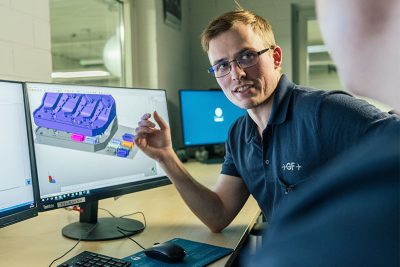

Design

Our team of experts uses CAD to optimise the design of the components. In this context, topology optimisation is an important tool for learning from nature and for designing components bionically. In this way, we strive to meet customer requirements as detailed as possible and ensure optimal manufacturing results. In cooperation with our customers, costs and function can be optimised. Especially by using 3D printing, functional integration can be combined with maximum design freedom. Together we shape the future.

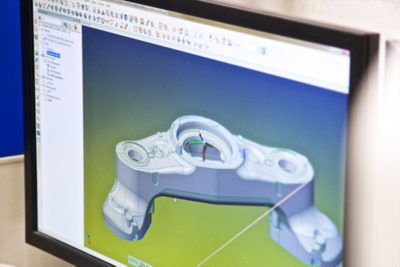

Simulation

A detailed understanding of the part geometry and process parameters ensures that we meet our customers’ requirements in the best possible way. With the help of simulation, time- and cost-intensive tests can be significantly minimised in advance, which gives our customers a tremendous opportunity to reduce time-to-market.

Critical areas in the part are identified at an early stage and can be optimised specifically. In addition, this ensures the high quality standard that GF offers its customers and, by reducing scrap and rework, increases sustainability throughout the entire process.

Castability / Data preparation

To produce prototypes, spare parts or smaller quantities, we use our innovation center for 3D printed sand cores. To print sand cores, the digital CAD model is divided into layers, and later, the laser in the printer will print these layers into the job box - one by one. The preliminary modeling work is necessary to maximise the utilisation of the job box: we fit as many parts and structures as possible into the available space to increase process efficiency and sustainability.

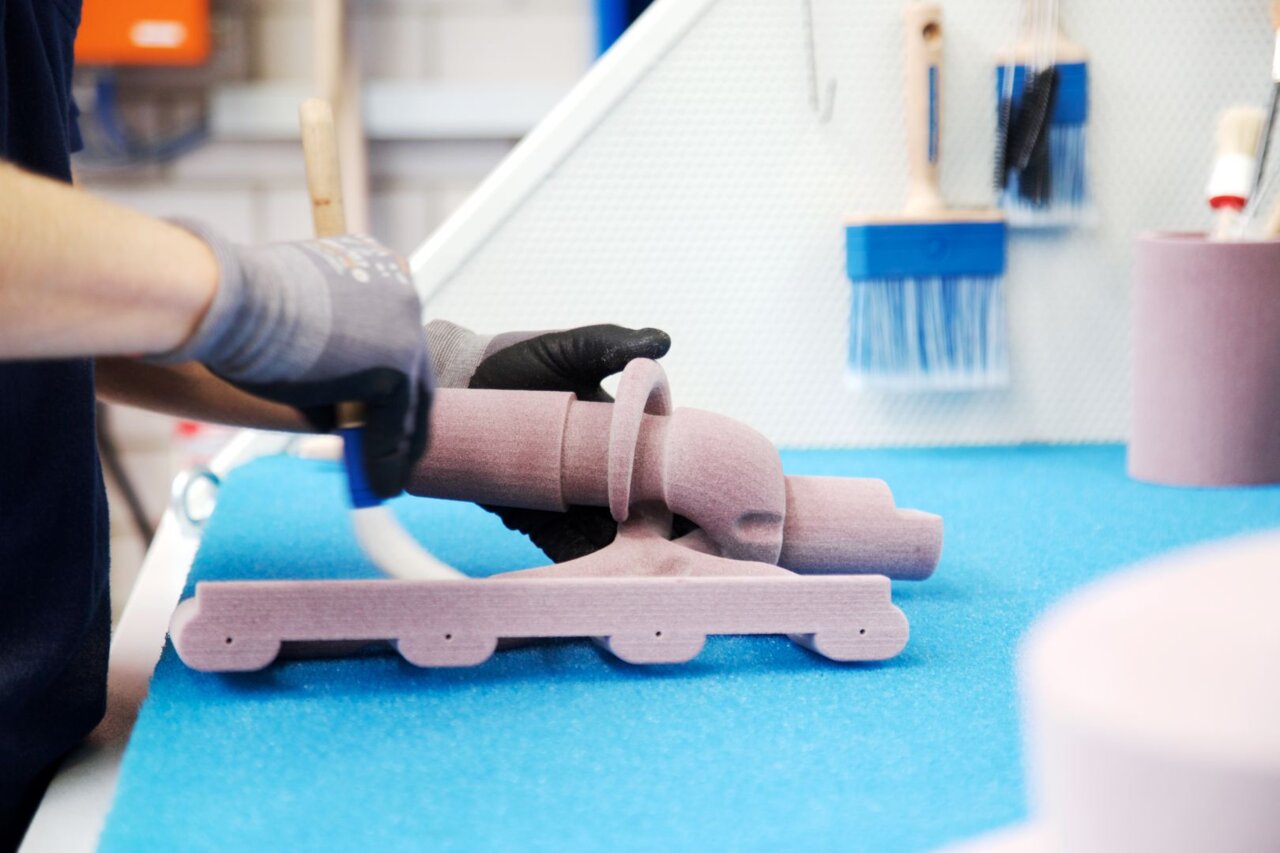

3D printing

Based on the corresponding part slices, sand is distributed in the job box, followed by a binder. Print layers are applied one by one. After each application, the job box moves downward by the thickness of one slice. The steps repeat until the entire job box is filled and the desired sand model is completely built up. The printed cores and moulds are unpacked and the excess sand gets removed and reused, which ultimately contributes to a circular economy.

Casting

Our moulding box, the largest in use across Europe and North America, increases process speed, accuracy and efficiency. By printing both cores and moulds, we can provide parts with short lead times for early stage testing, assembly testing and more. Various materials are available for producing prototypes and for serial production: grey cast iron, steel, and aluminium (also in cooperation with other foundries). State-of-the-art automation is used to clean the parts via shot blasting/grinding.

Finishing / Quality testing and assurance

In order to ensure a reproducible high quality for each component, we carry out a variety of tests. For example, ultrasonic tests and magnetic crack testing, also dye penetration testing or X-ray testing. Based on these procedures as well as our know-how, our customers can be sure that their component meets the desired requirements and withstands the calculated loads.

Coating

We offer various services for finishing and refining components following quality testing. For example, to reduce unnecessary costs, we provide support for design optimisation before starting series production. After the parts are produced, we apply various coatings, such as a primer or top-coat, based on customer specifications. This provides corrosion protection during transport and warehouse storage. The parts are immediately ready for further processing or use upon delivery with no additional time or expense for removing rust film.

Machining

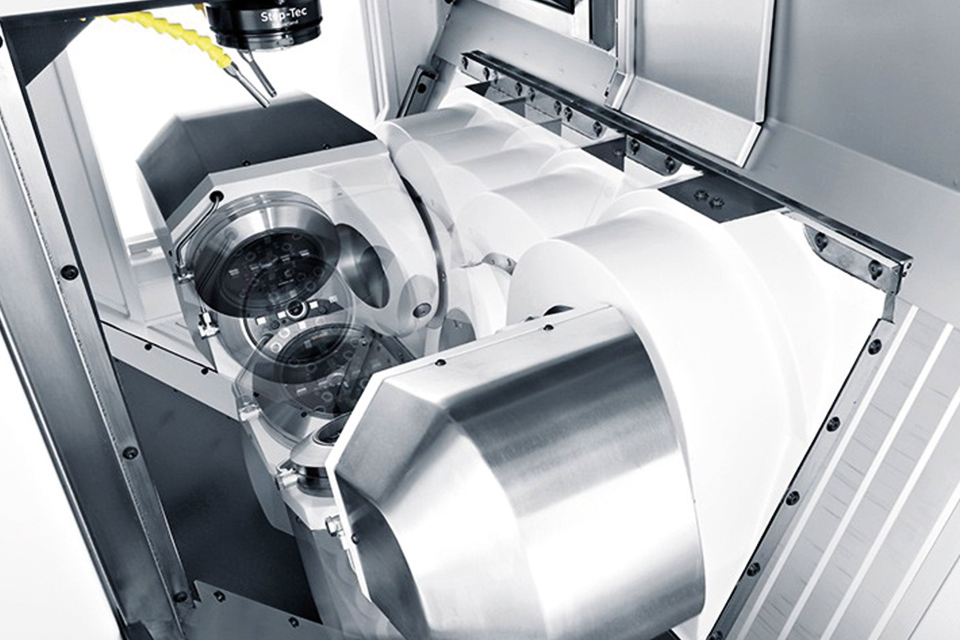

Components can also be machined following production to meet customer requirements. These processes can be performed by external partners or in-house, which is preferred for 3D-printed parts. Our equipment includes a 5-axis CNC milling center and measuring machines. We also assemble components and sub-components and provide various logistics services. Our customers can expect quick delivery times and 3D-printed parts that are immediately ready for installation. Moreover, because GF is a full-package supplier, customers get everything from a single source. Our hands shape your success.

Our solutions

Portal Axle Housing

| Application | Agriculture machinery |

| Process | Iron sandcasting |

| Material | GJS 500-14 |

| Weight | 343.0 kg |

| Value Chain | Casting |

- Large-scale casting

- Produced with 3D-printed sand cores

Paralevel

| Application | Chassis/"Leveling" |

| Process | Greensand moldin |

| Material | GJS 500-7 |

| Weight | 420.0 kg |

| Value Chain | Casting, machining, top coat |

- Complex structure

- Difficult regarding feeding

- GF managed the complete supply chain

Discover our apprenticeship possibilities

Our certificates

Certificates of our location for iron casting in Leipzig

- ISO 14001 - GF Casting Solutions Leipzig GmbH (PDF/ 299 KB)

- ISO 50001 - GF Casting Solutions Leipzig GmbH (PDF/ 162 KB)

- IATF 16949 - GF Casting Solutions Leipzig GmbH (PDF/ 158 KB)

- ISO 9001 - GF Casting Solutions Leipzig GmbH (PDF/ 157 KB)

- ISO 45001 - GF Casting Solutions Leipzig GmbH (PDF/ 318 KB)

- TISAX® Assessment - GF Casting Solutions Leipzig GmbH (PDF/ 114 KB)