We are uniquely positioned to offer the entire value chain, from the production of internal ceramic cores to the machining of components.

All of our products are manufactured in our four plants in Switzerland and Romania.

Investment Casting

Industrial manufacturing technology based on the lost-wax process used in the aerospace and energy industry to produce airfoils and structural parts with complex shapes and cooling systems.

We offer

- Gating & Tooling designs

- Casting filling, solidification

- Defects prediction simulation

- Core & ceramics recipe definition and production

- Equiax, Single Crystal and Direction Solidified capabilities

- Machining

Process Capabilities

- Ingot / Master Heat*

- Ceramic Core

- Wax

- Shell

- SX/DS Furnace

- EQX Furnace

- Shell Removal

- Core Leach (hollow parts only)

- (HIP)*

- Heat Treat

- X-Ray

- Grain Etch

- Laue (SX/DS only)

- FPI

- Ultrasonic Wall Thickness (hollow parts only)

- Metallurgical Laboratory and Mechanical testing

- CMM

- Straightening

- White Light / Blue Light inspection (optional)

*external

Alloy Specifications

Nickel

| EQX | DS/SX |

In 100 In 600 In 625 In 713 LC In 718 In 738 LC In 792 In 939 In 939 (Weldable) Mar M 004 Mar M 247 Rene 41 Rene 77 Rene 80 Rene 125 Rene 142 C263 C1023 U500 GTD 111 GTD 141 GTD 222 GTD 262 GTD 741 B1914 Hast X CM 2100 CM 186 LC |

CM 186 LC TM CM 247 LC TM CMSX 4 TM CMSX 8 TM DS 200 IN 792 (DS) AM 3 GTD 111 LZ DS 200 MC 2 Rene N5 Rene 220 (DS)

|

| Plus many other customer proprietary alloys | |

Iron

17-4 PH

X12Cr13

X30Cr13

AISI 304

AISI 316L

AISI 347

420

N-155

X22 Cr Mo V 121

Z 20 CNW 22

N155

Kovar

X14Co

Jethete M152

17-4 PH X12Cr13 X30Cr13 AISI 304 AISI 316L AISI 347 420 N-155 X22 Cr Mo V 121 Z 20 CNW 22 N155 Kovar X14Co Jethete M152 |

Cobalt

X 40

X 45

FSX 414

FSX 414 SV

HS 21

HS 25 (L-605)

HS 31 (X-40)

Mar M509

Mar M509 (Weldable)

X 40 X 45 FSX 414 FSX 414 SV HS 21 HS 25 (L-605) HS 31 (X-40) Mar M509 Mar M509 (Weldable) |

Critical Dimensions per Product

| Class Product | Critical Dimension |

| Blades DS/SX | Height 500 mm |

| Blades EQX | Height 700 mm |

| Vanes EQX | Weight 60 kg L1*L2= 900 x 700 mm |

| Structural EQX | Weight 55 kg Ø 800 mm |

| Structural Air Melt | Weight 50 kg Ø 700 mm |

Investment Casting and post-processing

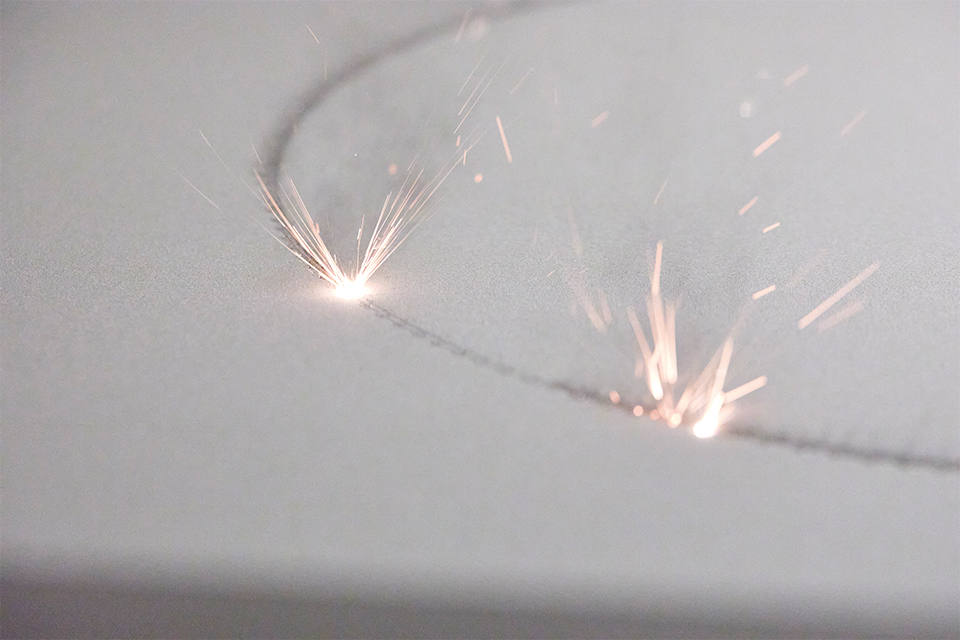

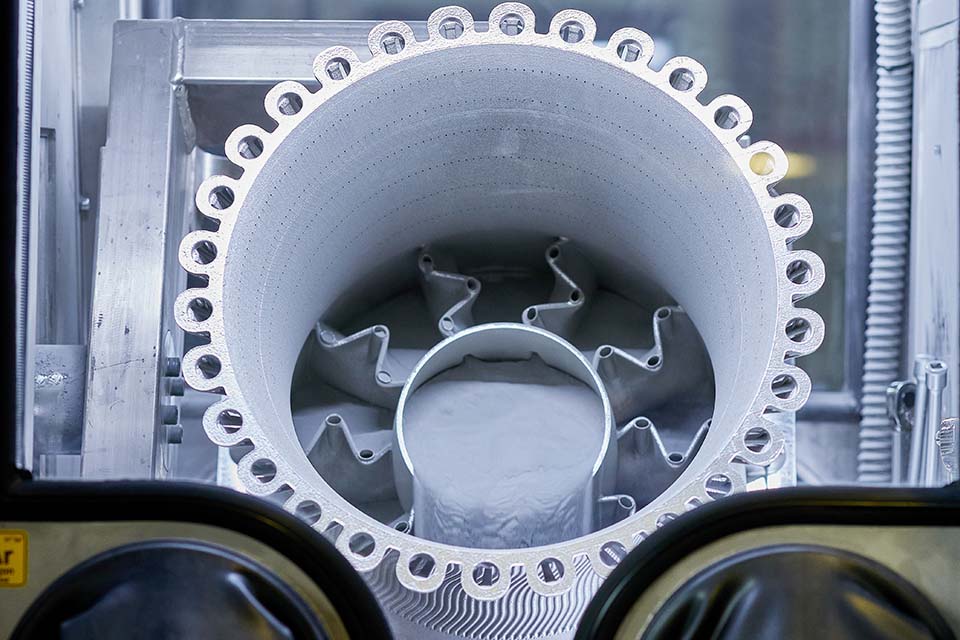

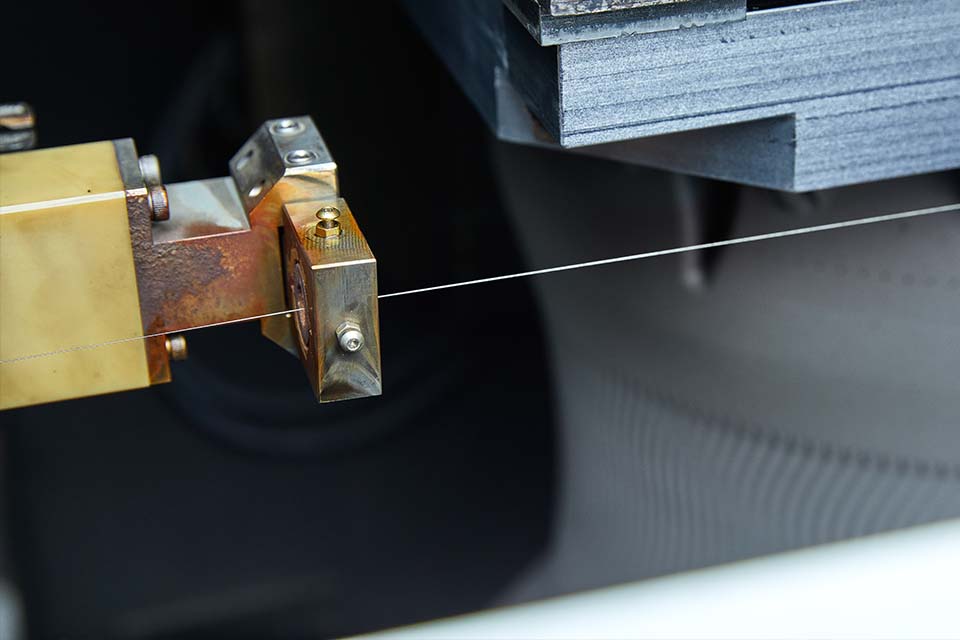

Additive Manufacturing

Metal 3D-printing for aerospace, space, motorsports and energy solutions

With the AMotion Center in Switzerland, GF has founded a strongly focused competence center for Additive Manufacturing . The additive manufacturing process maximizes the design flexibility and allows the integration of additional functions due to the absence of tooling. Geometries are no longer limited to the possibilities of traditional technologies. With printing space as big as 500 x 500 x 500 mm, we offer serial production of large additive manufactured components with extremely complex shapes integrating more details and functions.

We support you with long-standing experience from decades!

- From the very first design concept to serial production

- Topology optimization from the very beginning

- Selection of most suitable alloy for high performance applications

- Combination of several parts and high-level functional integration

With our expertise, we provide the ideal design with funcitonal integration.

Value add in metal 3D-printing

Machines and material capabilities

| Technology | Laser Powder Bed Fusion (EOS M290) | Laser Powder Bed Fusion (DMP Factory 500) | Research and development outlook |

| Materials | Inconel 718 Inconel 625 Hastelloy X AlSi10Mg Inconel 738 Haynes 282 |

Inconel 718 Hastelloy X Inconel 625 Inconel 738 Haynes 282 |

Material on-going: AlSi10Mg A3-4AM Titanium |

| Dimensions | 250 x 250 x 280 mm | 500 x 500 x 450 mm | 500x500x500 mm |

| Laser type / nr | 400 W | 500 W X 3 | 500 W X 3 |

| Ra 6÷8 µm | Ra 4÷7 µm |

Areas of application

Energy

Space

Aerospace

Motorsport

New challenges need new technologies

GF is ready to realize your 3D-printing challenge!

With GF as your Additive Manufacturing partner you benefit from:

- Short development cycles

- Unlimited possibilities in terms of shape

- Wide variety of materials

- Know-how in serial part production

- In-house Research and Development team

- Post-processes in-house

- Fully certified value chain

Our certificates

Product quality and customer service have always been the main goal for GF. The Management-Team in Novazzano keeps control of the Quality Management System by performing regularly reviews aimed at verifying its adequacy, effectiveness and efficiency, ensuring that the objectives assigned in accordance with the Quality Policy have been attained and designing improvement and risk mitigation plans where necessary. The loyalty of our customers and compliance certification and accreditation to the international EN 9100; ISO 9001 and ISO 14001 standards are testimony to the effectiveness of our Quality Management System.

Nadcap certified production of Investment Casting and Additive Manufacturing

Certificates of our location in Novazzano & Stabio

- NADCAP Welding - GF Casting Solutions Novazzano SA (PDF/ 357 KB)

- NADCAP Welding - GF Casting Solutions Stabio (PDF/ 365 KB)

- NADCAP Non Destructive Testing - GF Casting Solutions Novazzano SA (PDF/ 374 KB)

- NADCAP Heat Treatment - GF Casting Solutions Novazzano SA (PDF/ 374 KB)

- ISO 9001 - GF Casting Solutions Novazzano SA (PDF/ 541 KB)

- ISO 9001 - GF Casting Solutions Stabio (PDF/ 162 KB)

- ISO 14001 - GF Casting Solutions Novazzano SA (PDF/ 256 KB)