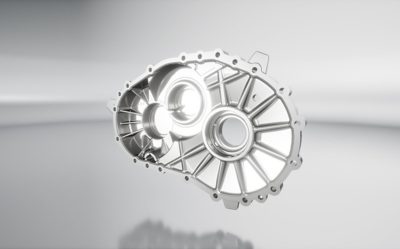

Challenges & Special Features

This e-axle housing, which is part of the electric drive unit, needs to fulfill very high leakage proof standards. During the die casting process, extremely high temperatures and pressures are shaping the thin-walled component and many parameters need to be 100 % accurate. To optimize the component for a leakage rate less than 0.5 %, several optimization loops are usually needed before the reliable and high-quality serial production can start. Key is to reach the right balance of all parameters.