Challenges & Special Features

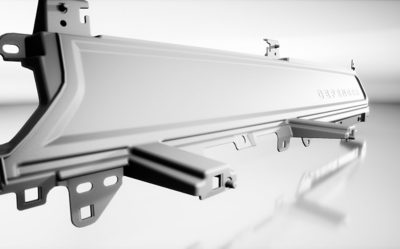

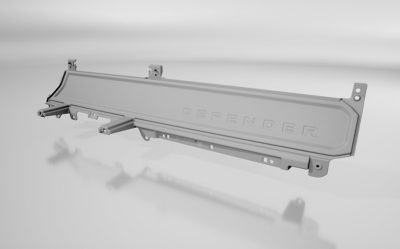

The finisher passenger side is mounted directly in front of the driver and passenger and ultimately gets part of the vehicle’s driving experience. It has a special meaning to GF: it is the first component ever, which is visible in the vehicle's interior. To ensure that the part has a smooth surface finish, free from any cracking or impurities, GF works very precisely and ensures optimal workflows. The component integrates many connection points to its surroundings, such as airbags, nagivation display, or the globe compartment, which ultimately saves time, material, labor, and energy for the installation.