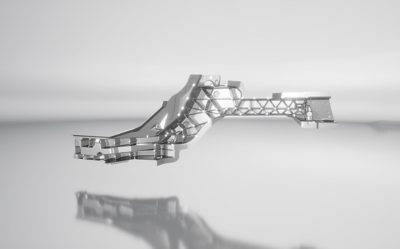

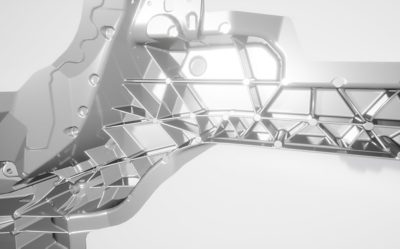

Challenges & Special Features

Overcoming the hurdles of serialization and achieving the high quality requirements have been challenges from technical perspective. Together as a strong team and with the customer, GF Casting Solutions excelled in fine-tuning the mechanical properties and dimensional quality. The mating surfaces on the rear side member towards the front of the car warrant optimal dimensional quality.