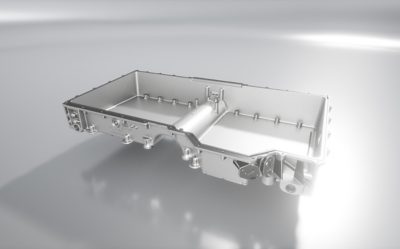

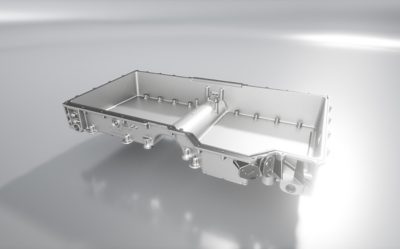

Challenges & Special Features

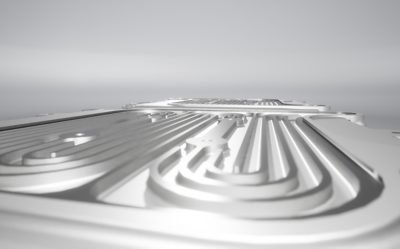

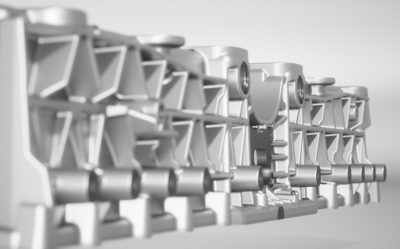

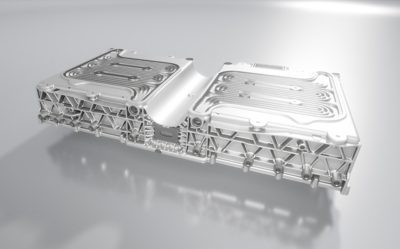

During production, the main challenge was to avoid deformations after machining and to ensure that no leaks occurred after welding. The size of the part, closed by welded covers, also deserves special attention as it is cast in one piece. Additionally, the component features an integrated cooling system as well as integrated connection points for surrounding body and structure parts. According to the customer, the vehicle emits about 75 % less CO2 per kilometers than identical models with combustion engines.