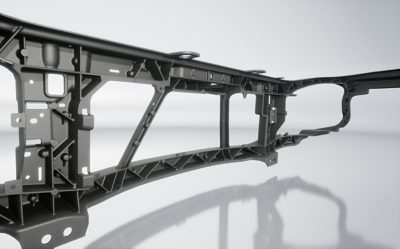

Challenges & Special Features

This big lightweight magnesium component is located at the vehicles front. It is a carrier for the front structure where lighting systems and the central air intake system are fixed. Highlights in terms of production process complexity are the two areas of the component, which are visible from the outside. They require a high-quality surface finishing (surface A requirement). In addition, the big, long and thin-walled component needs to meet tight tolerances. It is a great example for light structural parts with big dimensions and high integration of functions.