The company GF meco eckel GmbH & Co. KG is one of Europe's leading and top-selling tool and die makers.

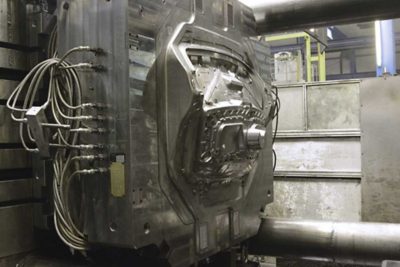

We specialize in the development and production of system solutions using high-pressure die-casting and permanent die-casting technology for the automobile industry. Our customers include all major automobile manufacturers and their foundries as well as the high-pressure die-casting foundries of GF Casting Solutions.

As part of the GF family, we in Biedenkopf-Wallau place high value on innovation and teamwork. We put our lifeblood into making tools and models that meet the highest demands for quality and precision. Moreover, we pursue clearly defined goals and sustainability within the GF-wide Strategy 2020.

Would you like to learn more about us and our core competence? Or are you interested in a career in our company? Learn more:

?qlt=82&ts=1638635548129&dpr=off)

?qlt=82&ts=1638635536175&dpr=off&crop=(157,28,841,594)&crop=(157,28,841,594)&crop=(157,28,841,594))

&crop=(5,172,1208,683))