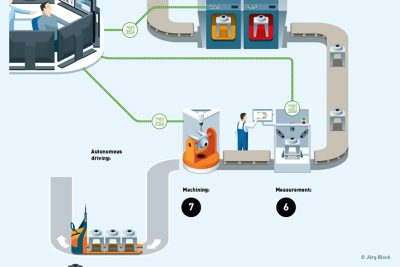

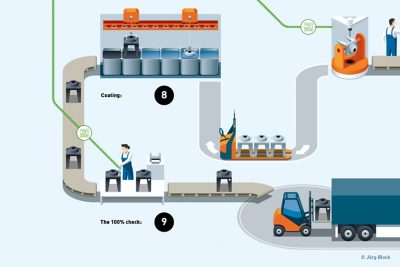

Automation at GF Casting Solutions

Find out in our video how we improve our processes with digitalization and a high level of automation in the production of our high-pressure die-casting facilities

Please accept all cookies to view the youtube video content.

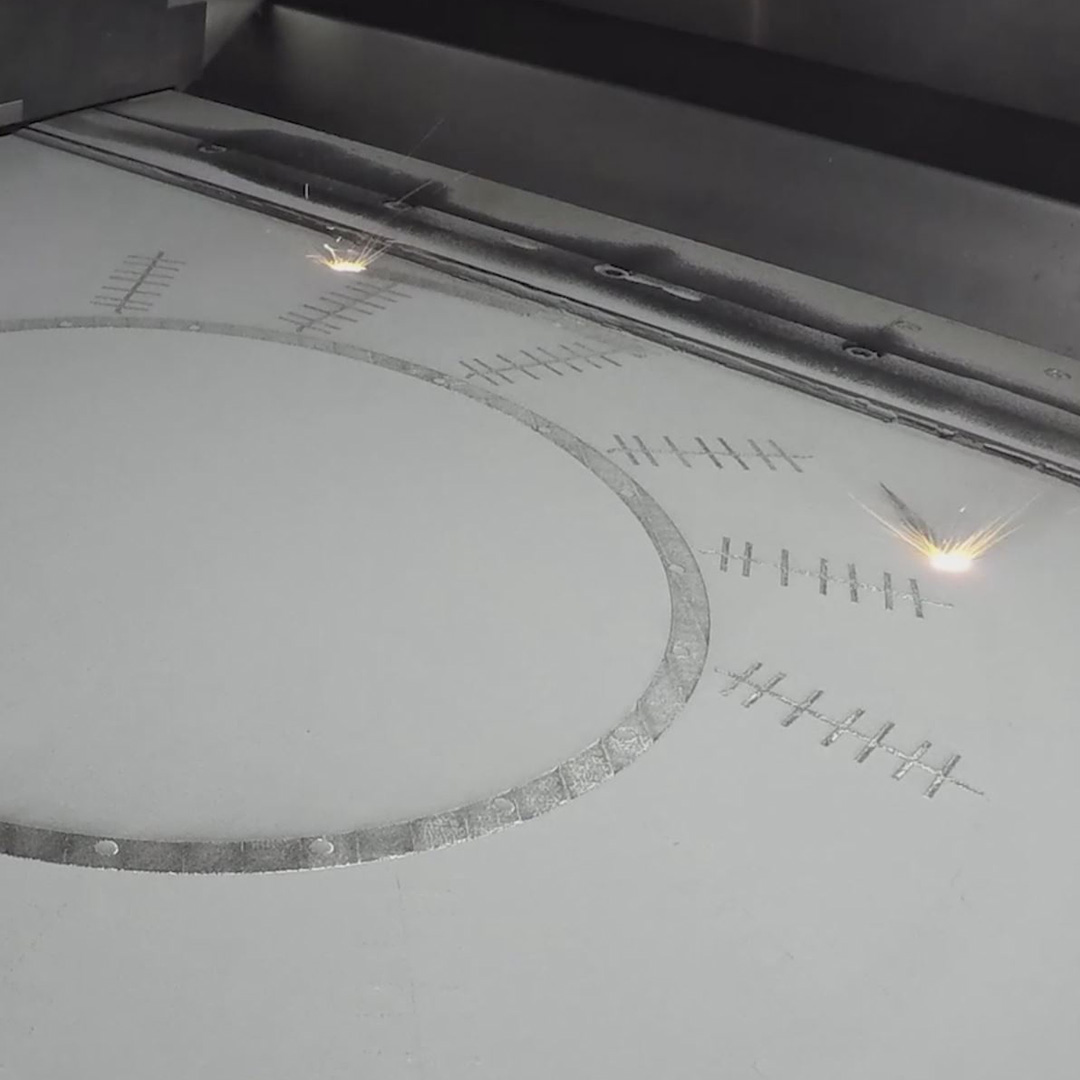

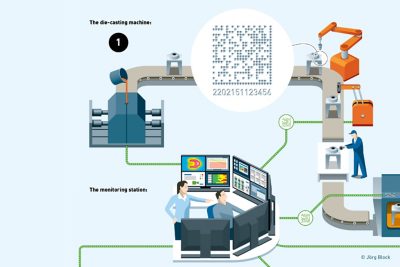

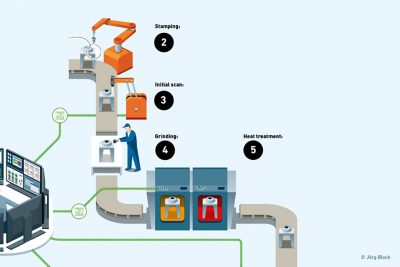

Each cast component gets a code

Find out how the data matrix code at GF Casting Solutions improves efficiency, ensures high quality, and enables sustainability when manufacturing lightweight components, such as shock towers.

Our development scope

With our central Research & Development department in our headquarter, Schaffhausen, Switzerland and in Suzhou, China, we want to support you with many years of experience, broad know-how and quality excellence in:

- Material development

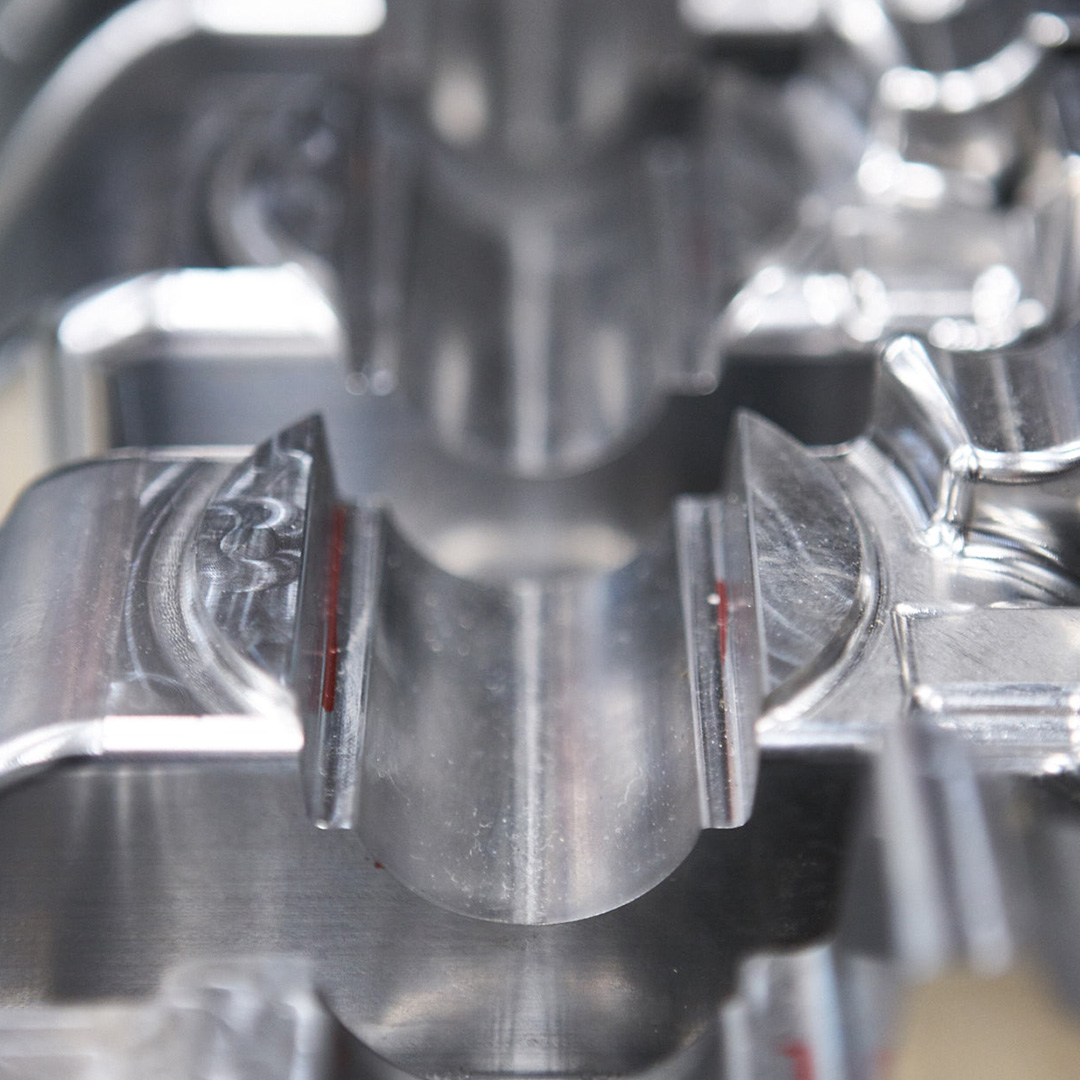

- Process development

- Design development

- Validation & testing

&crop=(97,62,855,568))

&crop=(88,57,846,563))

&crop=(95,64,853,570))