Batteries need safe housings

Common casting solutions for hybrid electric vehicles are battery housings made of aluminum, manufactured in the high-pressure die casting process. The housing offers a safe and yet weight-optimized shell for the sensitive battery.

With purely electrically powered vehicles, the batteries are becoming bigger. In combination with sheet metal parts, the housing can cover large batteries by providing more design freedom and the integration of functions into the cast parts.

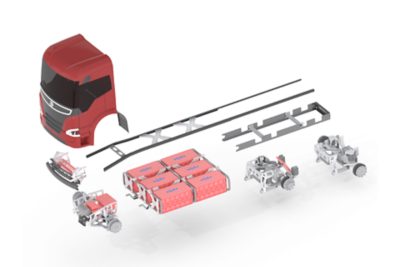

The example of the EDAG concept for a flexible and independent chassis system includes another possible solution: instead of one large battery, several packages could be tied together building packs of several smaller batteries. As in the EDAG chassis, the battery packs could be encased by cast solutions.

The complexity of the battery housings increases particularly as soon as additional functions are integrated into the cast components. In a current project by GF Casting Solutions together with a leading European vehicle manufacturer, the cast solution for the battery not only fulfills the crash relevant properties, but also includes a complex system for the cooling of the battery. With such complex functional integration into complex series components, light-metal die casting is an unbeatable manufacturing process!

?qlt=82&ts=1638635257366&dpr=off)