- Do you need support in component development?

- Do you need a fully functional prototype fast?

- Do you need large & complex parts with high quality?

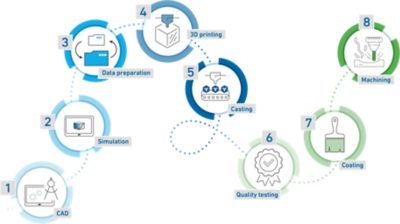

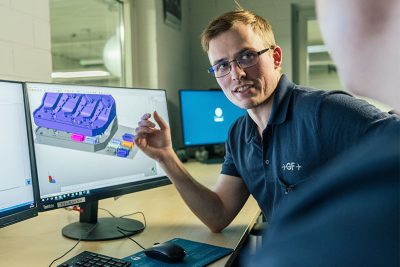

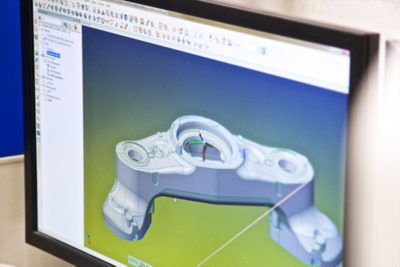

From the idea to series production, we supply everything out of one hand - GF Casting Solutions Leipzig operates the foundry with Europe's largest molding box for machine-molded iron casting. We offer all processes under one roof - from prototyping & sand 3D-printing, to series production in iron casting, coating and machining of components.

No matter what challenges you face, GF Casting Solutions supports you throughout the supply chain and strive to become your development partner. We offer comprehensive know-how and competencies for several market segments like construction equipment, forest and agricultural machines, hydraulics or robotics. Learn more about our process chain for prototyping and series production.