Accredited safety without compromises

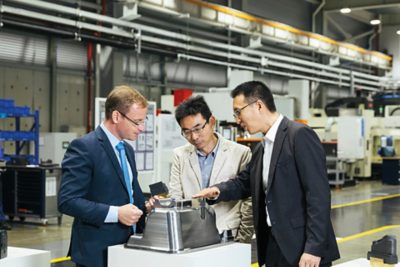

Our components offer the safety, quality, and function expected by our customers and by ourselves. In our accredited testing laboratory, we validate solutions and guarantee the high quality of our serial products.

Faster development thanks to validation

With state-of-the-art testing methods we test materials, entire components or required functions during the development phase and evaluate the processes. As a result, development loops between prototyping and serial production can be reduced: optimizing the costs as well as the time frame.

Our R&D lab offers a wide range of accredited testing methods:

- Static tests

- Multi-channel dynamic bench tests with up to four channels

- Impact tests

- Verification of numerical simulation and validation

- Measuring (strain gauge, GOM etc.)

- Prototyping

In addition to the testing of our GF Casting Solutions components, we also validate external products. Get in touch with us!