Focus on climate action and resource efficiency

Reducing GHG emissions through design and material composition

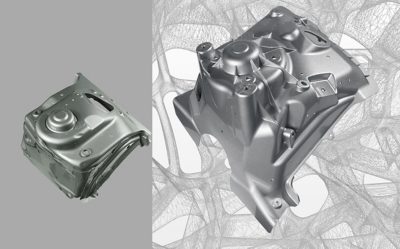

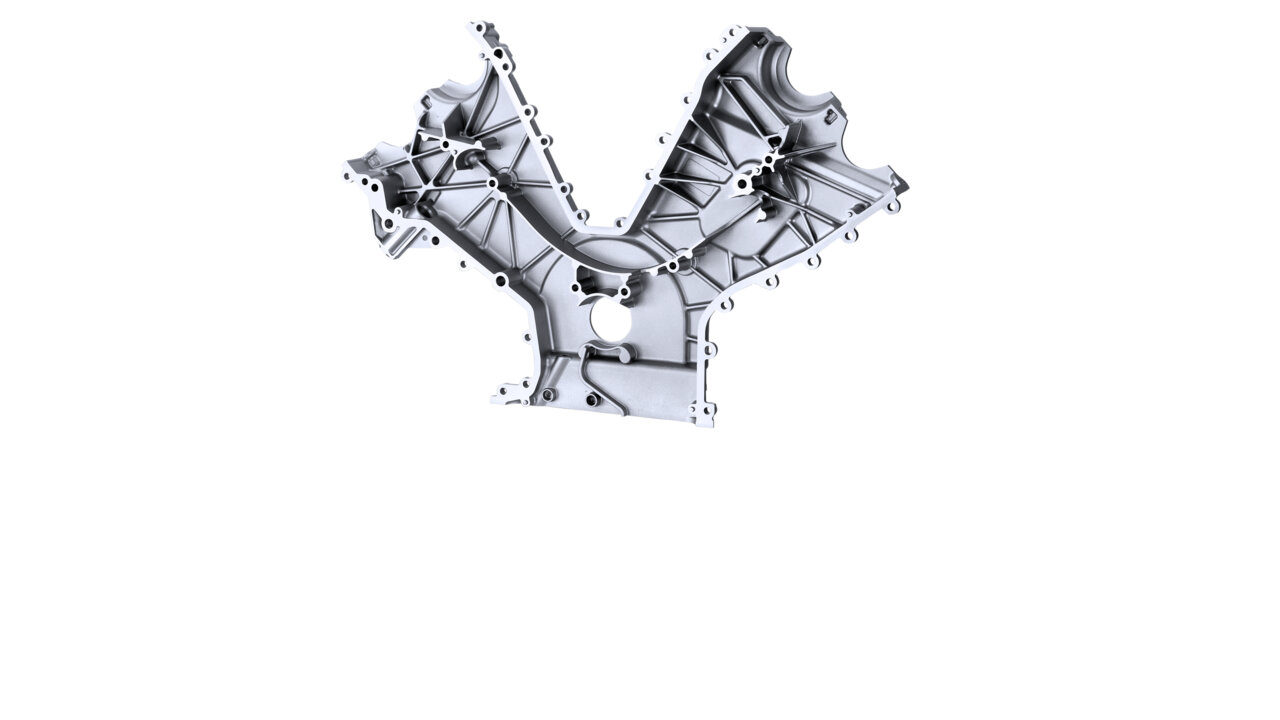

Leveraging bionic and lightweight design principles, continuously improves the weight of our components. This means, that less raw materials are used during the manufacturing process, leading to reduced GHG emissions throughout the entire life-cycle of a product.

Especially important for automotive applications, where weight reduction not only means a reduction in fuel consumption and the associated reduction in emissions, but also has a positive impact on driving behaviour.

Thinking towards a circular economy

Already today secondary aluminium and iron scrap play a major role in GF Casting Solutions manufacturing processes, with excellent rates of recycled materials used.

Together with our customers and partners, we work on new concepts to further increase the usage of recycled material to the highest extend physically possible.

Within the Sustainability Framework 2025 GF further focusses on increasing circularity and closed recycling loops, by leveraging the long-term casting expertise of our global foundries.