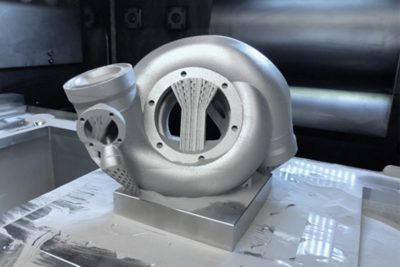

Our accelerative technology

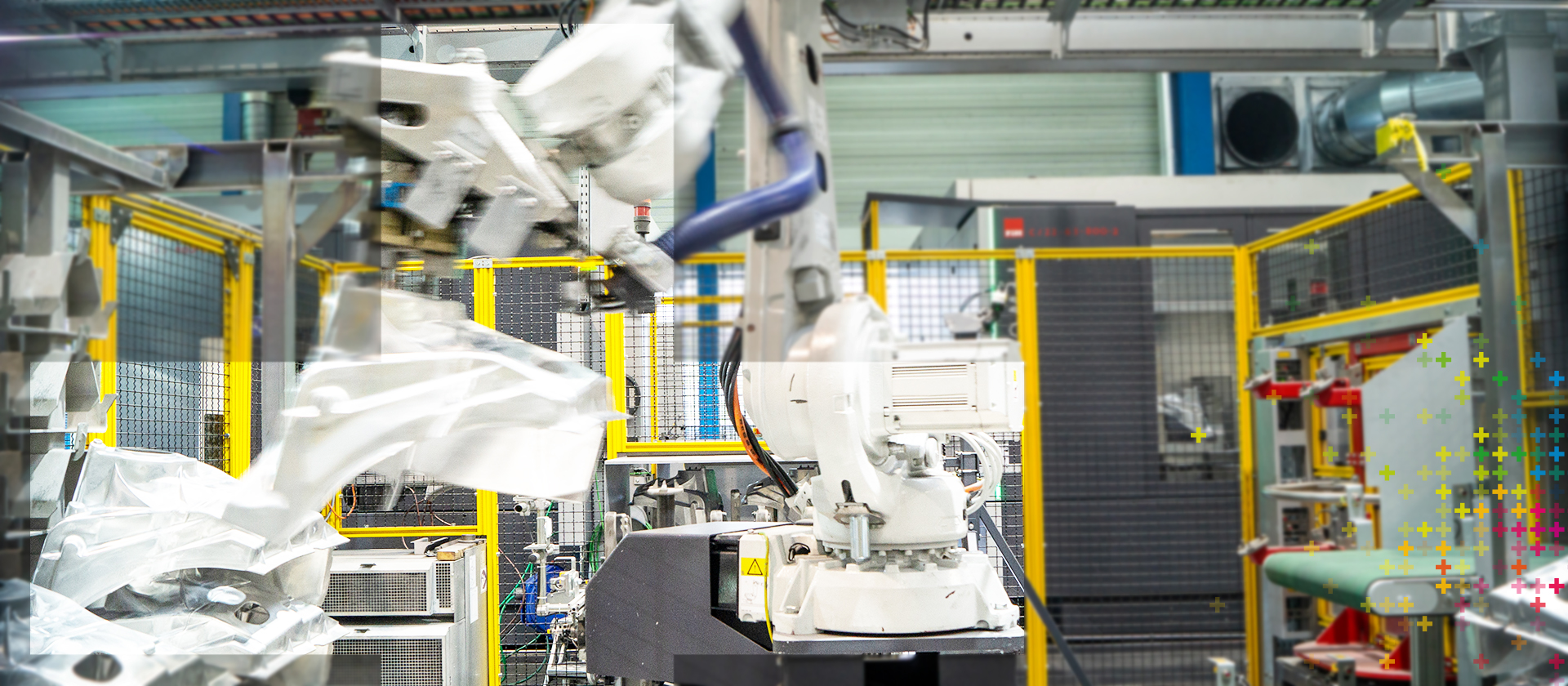

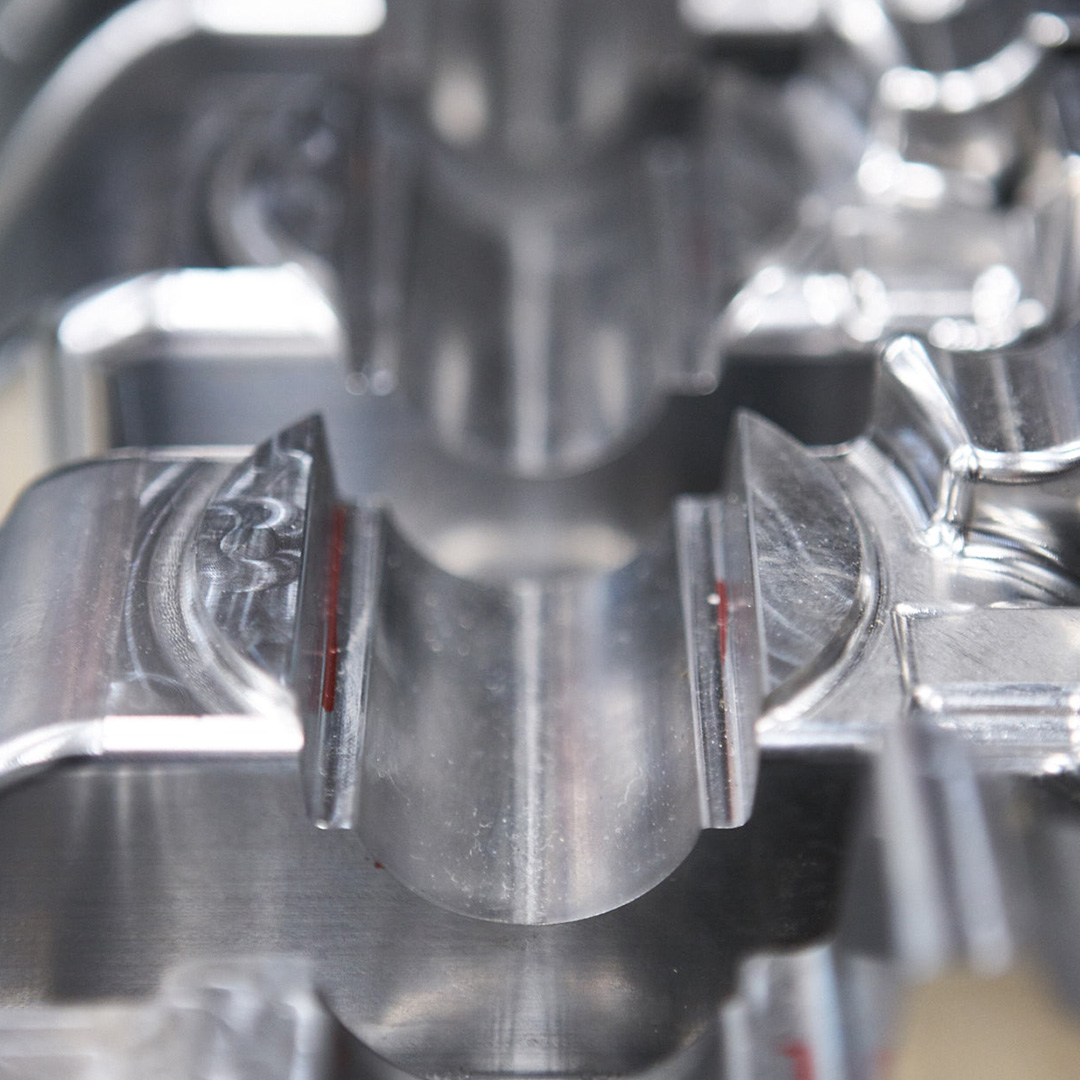

GF Casting Solutions has long-standing expertise in metal processing and serial production. With our manufacturing technologies, we develop and supply ready-to-mount solutions for customers in six market segments. With additive manufacturing, we provide even more speed and flexibility. Our solutions range from 3D-printed sand cores for iron casting solutions to the serial production of 3D metal printed solutions and additive manufacturing expertise.