Ready to win the race!

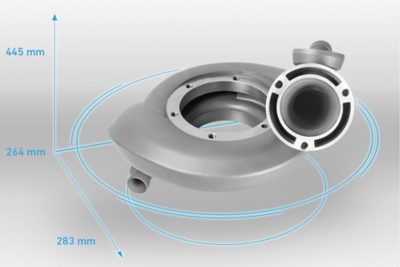

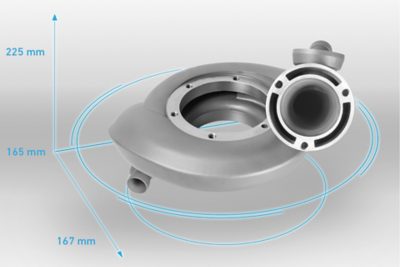

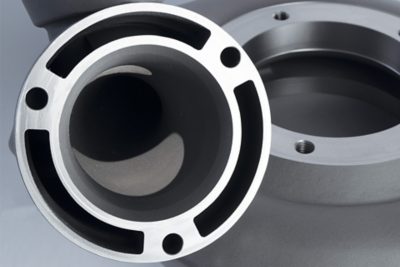

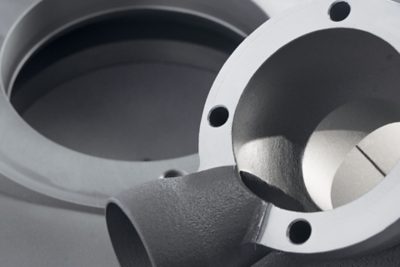

Winning the race without compromises - with highspeed and full flexibility in design - by relying on the proven additive manufacturing processes at GF. With the AMotion Center, you benefit from uniquely combined competences under one roof.

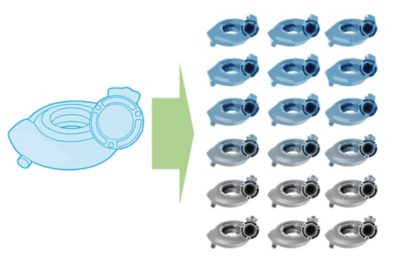

Our additive manufacturing process at GF is based on many years of experience with customers from various industries. Motorsport applications were among the first additive manufacturing projects we ever had and since then, we are absolutely passionate about it. Through our experience, the needs and challenges of motorsports engineers are not new to us - and we are ready to win the race together.

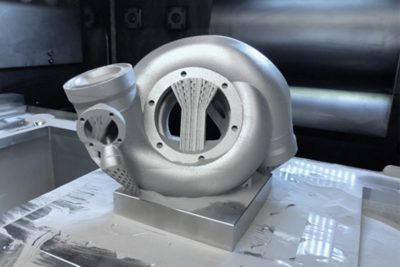

Setting new trends for the automotive industry

Speed is crucial in motorsports, not only on the race track, but also in product development and in adapting to latest engineering trends. Let us keep up with the pace to be ready for the next race together! We offer rapid prototyping, spare parts on demand and short lead times and support you from the very first design concept. We know the latest trends and are ready for changes and challenges when you are!