A testimonial for engineering excellence and agility

Recently, Boston Dynamics released a new generation of robots. The Stretch robot is a versatile robot that will be able to handle a variety of tasks, including unloading trucks, stacking boxes, and palletizing goods. According to Shirley Goh, Product Marketing Manager at Boston Dynamics, “the robot is different from anything else on the market”. It has a payload of 23 kilograms and a vertical reach of up to 3.2 meters, Shirley explains, making it suitable for use of warehouses, distribution centers, and manufacturing. In work environments of that kind, Stretch is able to take over tasks that are monotonous, repetitive, extremely physically demanding or dangerous for humans.

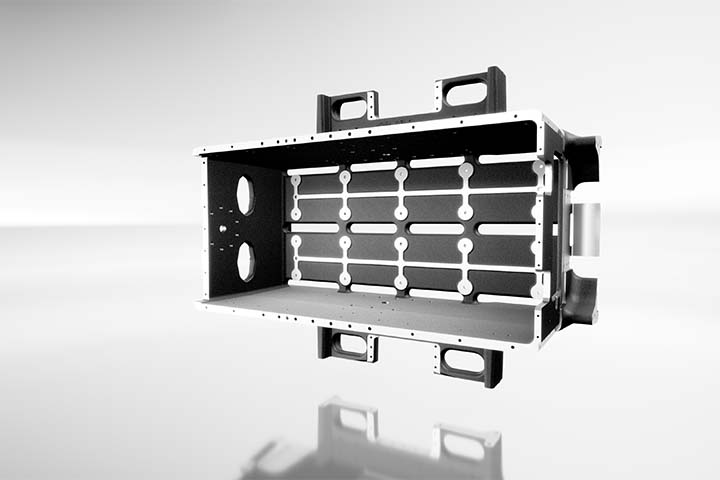

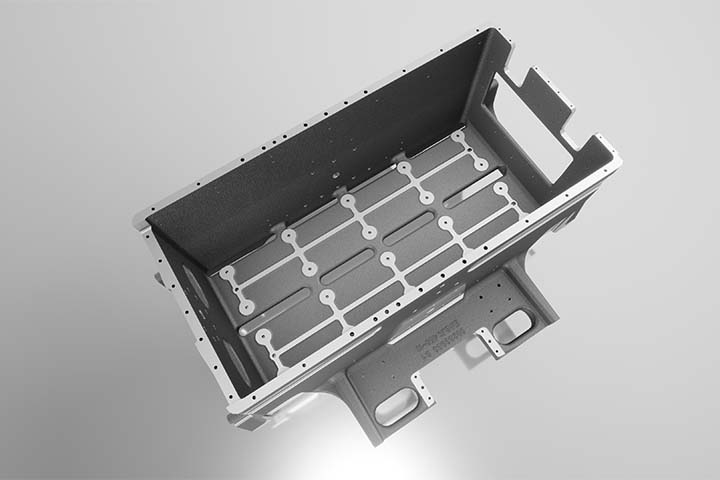

In other words, the robot relieves humans of the kind of work that is unpleasant or poses a threat to their health. The custom end-of-arm tool and arm are mounted on a mobile base, the chassis for which Boston Dynamics consulted GF Casting Solutions during development. As casting was not a core competence at Boston Dynamics, GF Casting Solutions was consulted during the overhaul of the design of the chassis for its fully automated production. Within only 12 weeks, GF Casting Solutions produced the first 7 prototypes in Leipzig, Germany, and delivered them to Boston Dynamics in the US. The prototypes were manufactured using a sand-casting method that involves 3D-printed cores. This approach allowed a high-quality surface finish alongside quick production while the lead-time and tooling costs remained minimal.