Taking the fast lane

Electric car manufacturers in China need suppliers with strong Research & Development capabilities and great operational efficiency. GF Casting Solutions has both. Through its successful partnership with emerging carmaker Aiways, the Division demonstrated that a global company can be a great partner for a startup in the Chinese market.

China’s auto sector has been cooling down, but it is still one of the fastest growing markets for electric cars. In the first half of 2019, about 490’000 electric cars were sold in China, a 56.6% increase from last year, according to the China Association of Automobile Manufacturers.

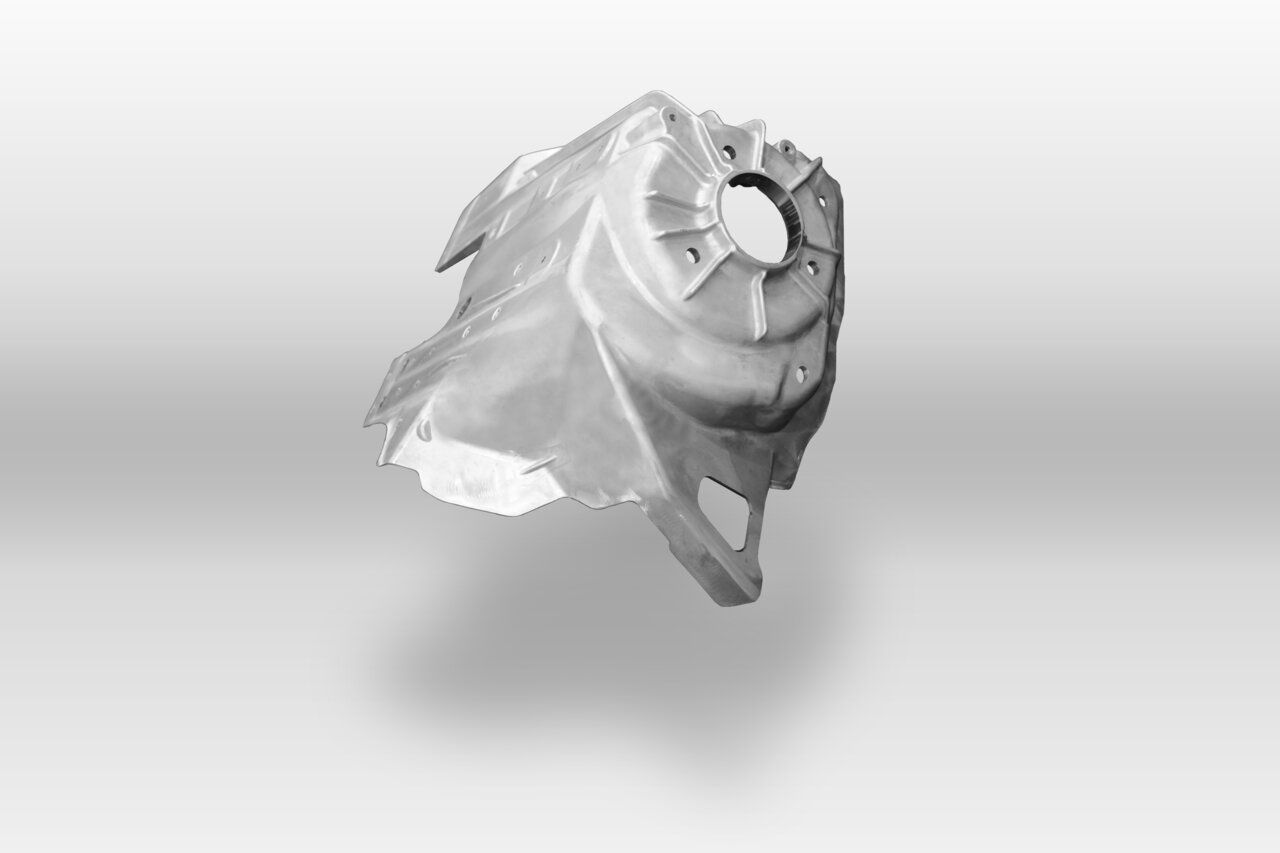

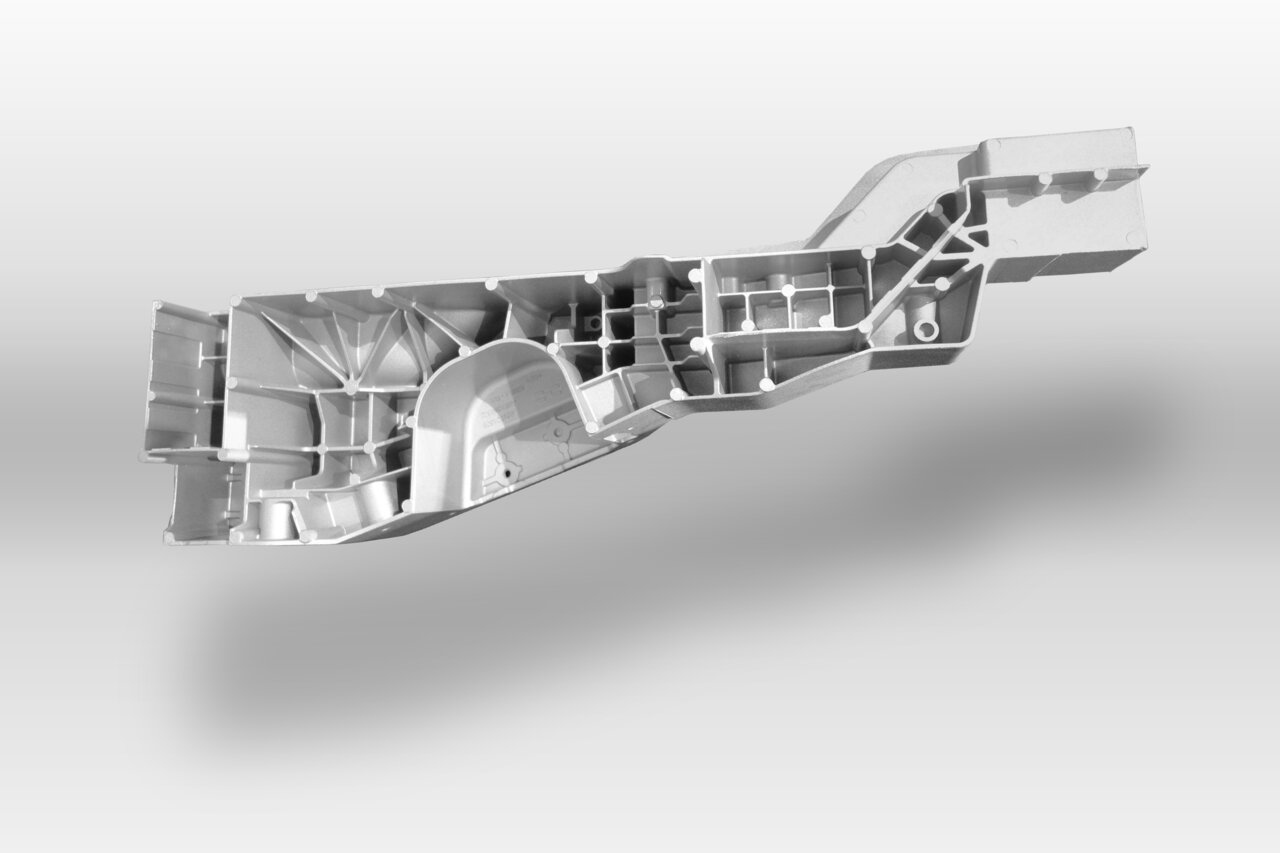

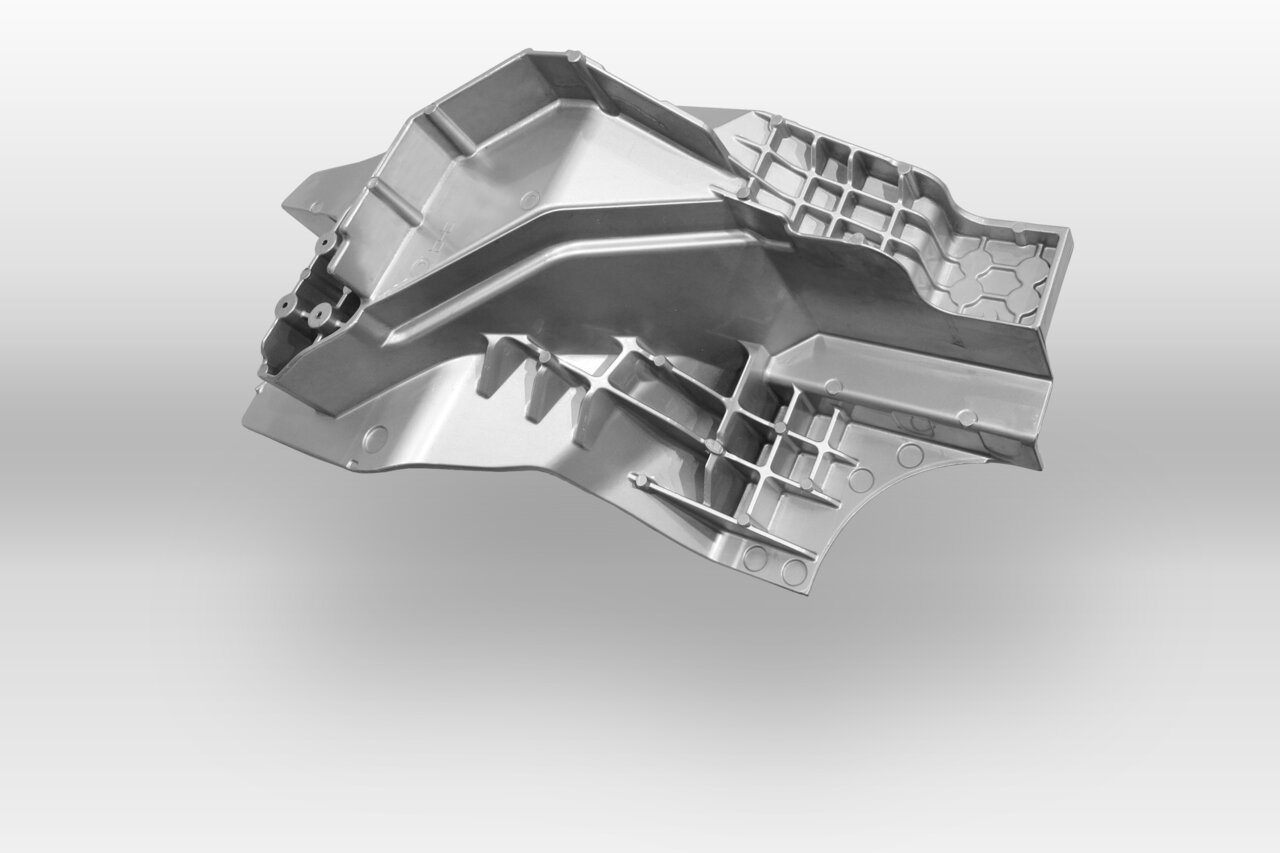

Aiways is one of the emerging carmakers trying to tap into the growing pie. The startup recently launched its first electric SUV called U5, with a reach of up to 503 kilometers. The SUV is equipped with six lightweight structural parts (two front shock towers and four torque boxes) produced by GF Casting Solutions. The aluminum components were developed and produced in less than 12 months.

?qlt=82&ts=1638635253197&dpr=off)

?qlt=82&ts=1638635244494&dpr=off)